Our Wholesale Hinged Segment Rings

Best selling hinged segment rings of 2024

Surgical steel hinged segment ring with outward facing prong set CZs, Thickness 1.2mm

Starting from 2.99$

Wholesale Pack of 10 surgical steel hinged segment rings, Thickness 1.2mm

0.99$ / pcs

316L steel hinged septum segment rings with forward facing prong set CZs, Thickness 1.2mm

Starting from 2.99$

316L steel hinged segment rings in a twisted wire design, Thickness 1.2mm

1.19$ / pcs

Titanium G23 hinged segment ring, Thickness 1mm

1.79$ / pcs

Titanium G23 hinged segment ring with outward facing prong set CZs, Thickness 1.2mm

Starting from 3.29$

PVD plated Titanium G23 hinged segment ring, Thickness 1.2mm

1.89$ / pcs

Titanium G23 hinged ball closure ring with 3mm ball, Thickness 1.2mm

1.99$ / pcs

PVD plated surgical steel hinged segment ring, Thickness 1.2mm

1.19$ / pcs

PVD plated surgical steel hinged segment ring, Thickness 1mm

1.19$ / pcs

PVD plated surgical steel hinged segment ring, Thickness 0.8mm

1.44$ / pcs

PVD plated 316L steel hinged ball closure ring with 3mm ball, Thickness 1.2mm

1.39$ / pcs

How to identify quality hinged segment rings

- The ring's general surface finish is already a good indicator of its quality; if you notice a dull surface, scratches, or imperfections with your naked eye, you are dealing with low-quality body jewelry, which should be avoided.

- Perform a Nickel swab test on 316L steel products to ensure they comply with the nickel release requirements.

- Notice that since 316L steel contains between 10% and 13% Nickel, any company selling 316L body jewelry with labels or descriptions such as nickel-free or 0% Nickel should instantly raise a red flag for you because they intentionally lie to and mislead their customers.

- For Products claiming to be titanium, there are 2 easy tests you can perform. Titanium G23 ASTM F136 Titanium / Ti-6Al4V-ELI. It has a specific gravity of 4.43 g/cm3 316L. Surgical steel, on the other hand, has a specific gravity of 7.94 g/cm3. This means that if you compare the same item in steel and titanium, the titanium one should be 44% lighter. The other test you can perform is with a small Dremel tool or angle grinder. When cutting titanium, the sparks should be bright white; when cutting 316L steel, the sparks should be orange. Note that with these tests, you can only confirm that the items are titanium but not if they are made of the correct grade of titanium for body jewelry, which should be ASTM F136.

- Evaluate the roundness of the hinged segment ring. Your best choice is to use a surgical steel or titanium taper one size larger than the ring. Place the ring over the taper and look for gaps around the circumference. Any clearly visible gaps indicate that the ring is not perfectly round.

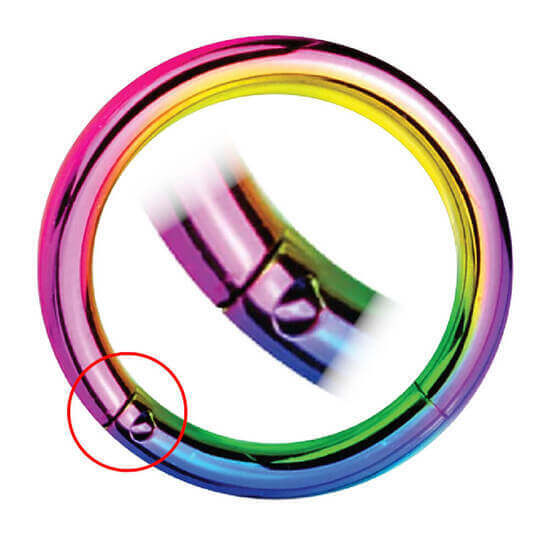

- Evaluate the ring's hinge. In high-quality rings, the pin and weld marks at the joint holding the small and large pieces together are almost invisible.

- Touch the ring's opening and feel for sharp edges that could injure a consumer. Cheap body jewelry frequently has sharp burs and unfinished edges.

- Move the opening part very gently to the left and to the right to see how much lateral play there is in the hinge. The movement should be minimal in good-quality hinged segment rings produced on expensive CNC machines with very tight tolerances.

- Check the force needed to open and close the ring and compare it to other rings of the same batch. If the forces required are very different from each other, this indicates a lack of consistency during production, and you can expect to receive a significant amount of defects when ordering from that supplier, even though some pieces might have decent quality.

- Open and close the same ring around 50 times. If, after that, the closure mechanism has become loose and doesn't hold firmly closed anymore, it's a clear indication that this is a low-quality hinged segment ring.

Examples of low quality hinged segment rings

Connection pin is clearly visible

Large gaps at the hinge

Surface is not mirror polished

Baht

Baht

US Dollar

US Dollar

Euro

Euro

British Pound

British Pound

Swiss Franc

Swiss Franc

Canadian Dollar

Canadian Dollar

Australian Dollar

Australian Dollar

New Zealand Dollar

New Zealand Dollar

Japanese Yen

Japanese Yen

Argentine Peso

Argentine Peso

Swedish Krona

Swedish Krona

Danish Krone

Danish Krone

Norwegian Krone

Norwegian Krone

Polish Zloty

Polish Zloty

South African Rand

South African Rand